![]()

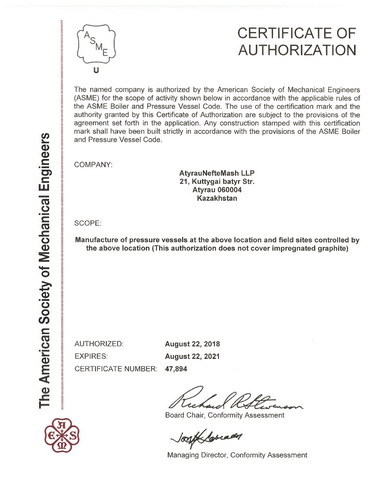

"АтырауНефтеМаш" сертифицирован по стандартам ASME и имеет соответствующие сертификаты со штампами "U", "U2", "R", "S".

«АтырауНефтеМаш» сертифицирован по стандартам ISO и имеет соответствующие сертификаты в области системы менеджмента качества

Машиностроительный завод «АтырауНефтеМаш» имеет собственные аккредитованные испытательную и химическую лаборатории.